The box arrives. Your customer is excited. You open it together, and your heart sinks. The beautiful glass chandelier inside is shattered. Your customer is disappointed. You’re embarrassed. You confidently tell them, “Don’t worry, I’ll get a replacement sent out right away.” You call your supplier… and that’s when the real nightmare begins.

Suddenly, you’re caught in a maze of emails, photo requirements, restocking fees, and arguments over who pays for shipping. You’re no longer a retailer; you’re a detective in a case nobody wants to solve. This frustrating scenario is where a supplier’s return policy goes from being a piece of fine print to being a critical factor in your profitability and reputation.

This guide will arm you with the knowledge to turn this potential weakness into a source of strength. We will dissect every component of a supplier’s return policy, reveal the hidden ways a bad one drains your profits, and provide a blueprint for what a great one looks like. This is a critical part of building a resilient and profitable business, a foundational concept we explore in our ultimate guide for independent lighting retailers.

Table of Contents

Decoding Wholesale Return Policies

The first step is to understand that a wholesale return policy is a completely different beast than the retail policy you offer your own customers. The mindset and the stakes are entirely different.

The Critical Distinction: B2C vs. B2B Returns

For you, the retailer, a flexible return policy is a powerful marketing and customer service tool. It builds trust and encourages purchasing. For your supplier, however, a return is a logistical and financial problem that needs to be managed and minimized. You cannot assume your B2B supplier will offer you the same generous “no questions asked” terms you offer your B2C customers. This is a crucial distinction that many new retailers miss.

The 3 Main Categories of Wholesale Returns You Will Face

Virtually all of your return situations will fall into one of these three buckets. A good policy will have a clear and distinct process for each.

- Shipping Damage: The product was damaged by the carrier (e.g., UPS, FedEx) while in transit to your store.

- Factory Defect: The product has a manufacturing flaw. This could be anything from faulty wiring to a crooked frame or a bad finish.

- “Retailer’s Remorse” or Customer Return: The product is in perfect condition, but you either over-ordered, or your end customer simply changed their mind.

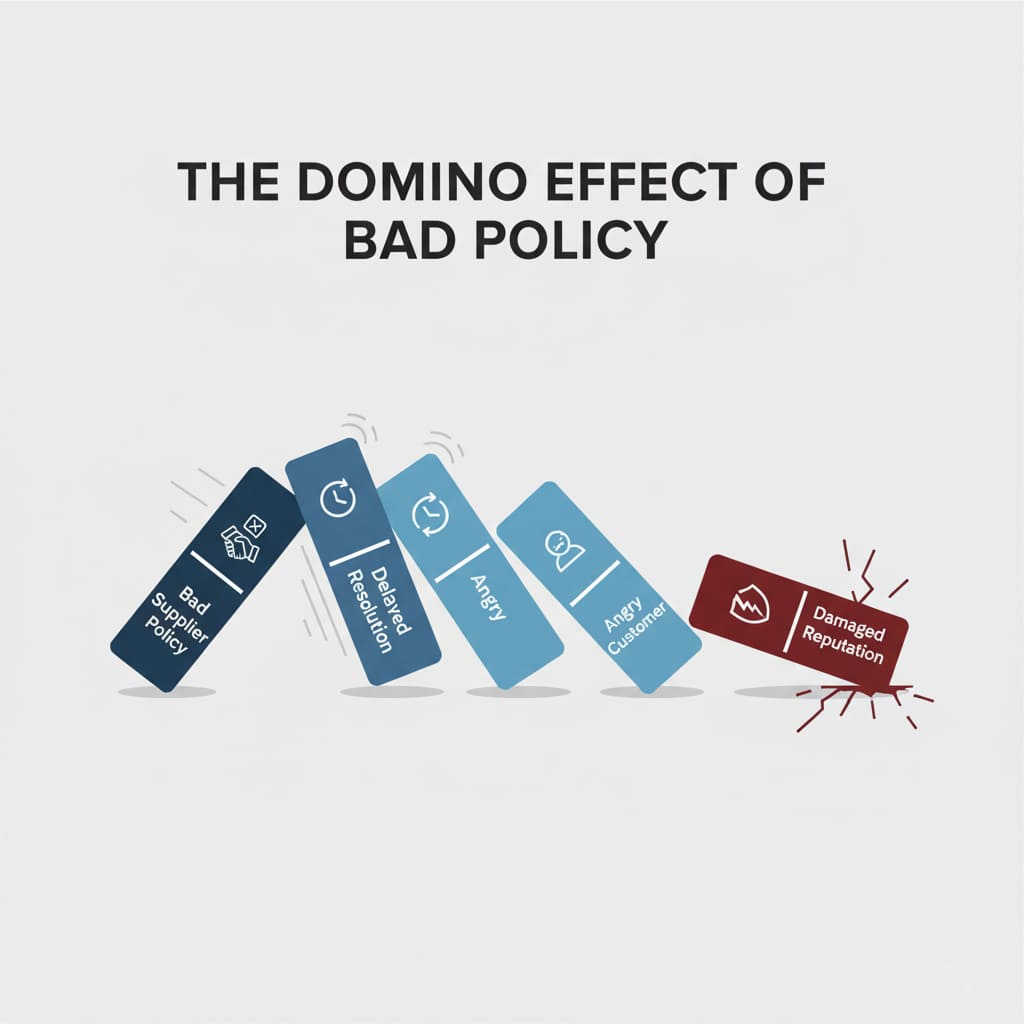

How a Bad Return Policy Bleeds Your Business Dry

A poorly written or unfair return policy is not just an inconvenience; it’s a silent drain on your resources. It attacks your business on three fronts: your finances, your operations, and your reputation.

Pillar 1: The Direct Financial Costs – The Obvious and the Hidden

Let’s do the math. The cost of a single bad return goes far beyond just the cost of the item itself. It’s a cascade of financial hits that can quickly turn a profitable sale into a significant loss.

| Cost Component | Description | Who Pays with a BAD Policy | Who Pays with a GOOD Policy |

|---|---|---|---|

| Lost Product Cost | The wholesale cost of the defective item. | You (if they refuse the claim) | The Supplier |

| Lost Profit Margin | The profit you would have made on the sale. | You | You (but is recouped on replacement) |

| Return Shipping Cost | The cost to ship the defective item back. | You | The Supplier (provides a label) |

| Restocking Fee | A punitive fee (15-25%) charged by the supplier. | You | $0 (Never charged on defects) |

| Your Labor Cost | The cost of your time spent managing the entire process. | You | You (but is minimized) |

With a bad policy, a single $100 defective item can easily end up costing your business over $150 in total losses. With a good policy, your loss is minimized to nearly zero.

These hidden losses can wreck your store’s finances over time. Protecting your cash flow is one of the most important jobs you have as a business owner. Learn more in our masterclass on Cash Flow Management.

Pillar 2: The Operational Chaos – The Time, Space, and Energy Drain

The financial cost is only part of the story. A bad return process creates operational chaos that distracts you from what you do best.

- The Time Suck: You become a part-time claims adjuster. The hours you spend taking photos, filling out complex forms, writing follow-up emails, and waiting on hold are hours you are not spending with customers, training your team, or marketing your business.

- The Inventory Black Hole: A bad policy often leaves the defective or damaged item sitting in your stockroom with no clear resolution. It takes up valuable physical space and eventually becomes “dead stock,” a problem that compounds over time. Learn how to deal with this profit-killing clutter in our guide to reducing dead stock.

Pillar 3: The Damage to Your Reputation – The Cost You Can’t Measure

This is the most dangerous cost of all. When a return is handled poorly, your supplier’s failure becomes your failure in the eyes of the customer.

The Angry Customer Caught in the Middle

You tell your customer, “I’m sorry for the delay, I’m just waiting to hear back from my supplier.” To your customer, this sounds like an excuse. All they know is that they paid for a product, it’s defective, and you are not solving their problem quickly. The delay in getting them a replacement or a refund directly harms your brand, not your supplier’s. A bad return process can instantly erase all the goodwill and trust you’ve worked so hard to build. It’s a direct violation of the principles of creating an unforgettable customer experience.

The Loss of Professional Credibility

The stakes are even higher with your trade customers. An interior designer who specifies one of your lights for a client’s project operates on a tight schedule. They cannot tolerate a four-week delay waiting for a replacement fixture. A single bad experience with a defective product that is not resolved instantly can cause them to blacklist you as an unreliable source. They will simply move on to a competitor who has a more reliable supply chain. This is a critical part of maintaining strong professional relationships. Learn more in our guide to building your trade business.

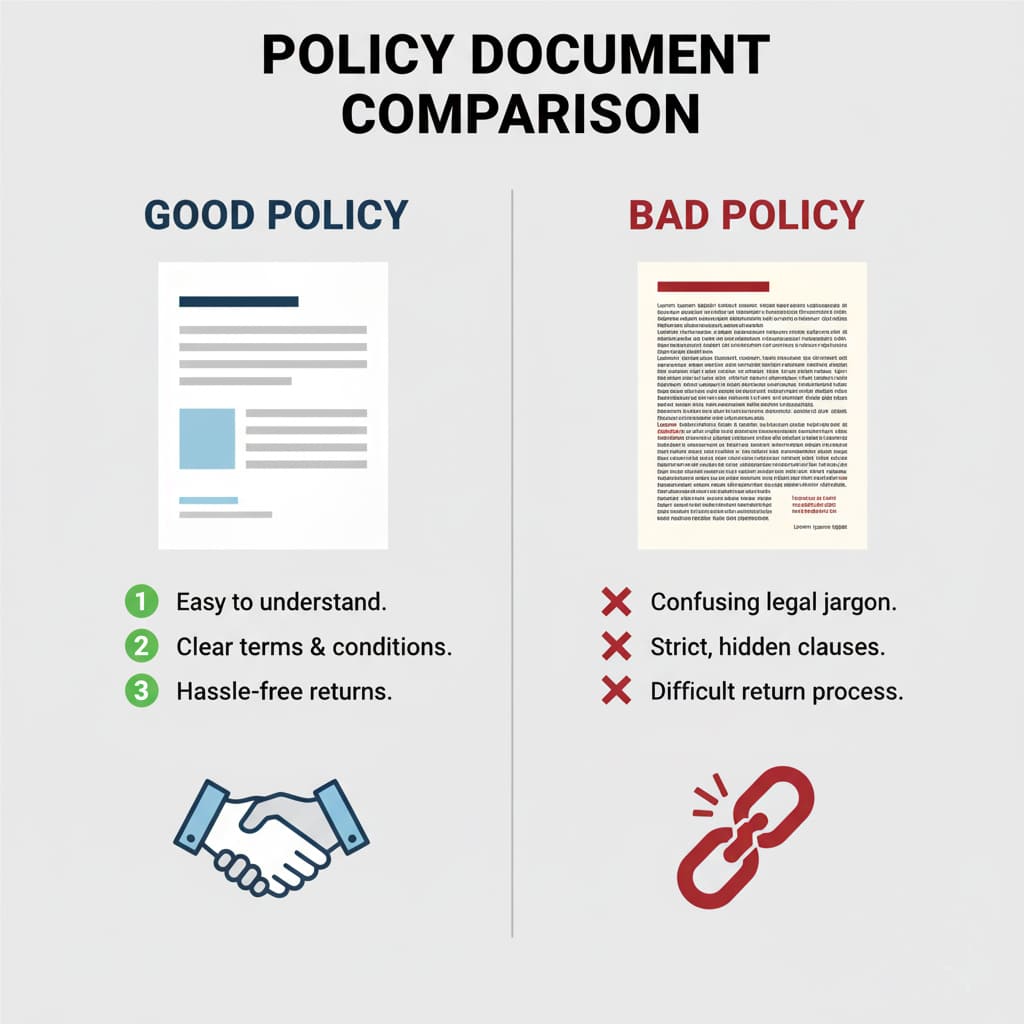

The Anatomy of a GREAT Supplier Return Policy

Now that we understand the dangers of a bad policy, let’s define what a great one looks like. A great return policy is not a sign of weakness; it’s a sign of a supplier’s confidence in their products and their commitment to a true partnership.

The 5 Hallmarks of a True Partnership Policy

- Clarity: It’s written in plain, simple English. It’s easy to find on their website. There are no hidden clauses or confusing jargon.

- Speed: It outlines a clear and fast timeline for reporting issues and, more importantly, for getting a resolution (like a replacement being shipped).

- Fairness: It clearly and unequivocally places the financial responsibility for shipping damages and factory defects on the supplier, where it belongs.

- Simplicity: The process for making a claim is easy and straightforward—ideally, a simple online form where you can upload a photo and get a quick response.

- Partnership: It may even offer a reasonable and clear policy for handling “customer remorse” returns, working with you to find a solution rather than simply saying “no.”

Green Flags vs. Red Flags: A Checklist for a Great Policy

Use this simple checklist to quickly evaluate any supplier’s policy.

| Policy Point | Green Flags ✅ (Signs of a Great Partner) | Red Flags 🚩 (Signs of a Risky Partner) |

|---|---|---|

| Reporting Window for Damage | A reasonable window (e.g., 7-14 days after receipt). | A very short, unforgiving window (e.g., “within 48 hours”). |

| Who Pays Return Shipping (on defects)? | The Supplier (They provide a prepaid shipping label). | You, the Retailer. |

| Restocking Fees (on defects)? | Zero. A great partner never penalizes you for their mistake. | Any fee at all. This is a huge red flag. |

| Resolution Offered | A fast replacement shipped immediately or an instant credit to your account. | A slow credit process, offering only to repair the item, or requiring you to wait for the claim to be processed. |

How to Vet a Supplier’s Return Policy (Before It’s Too Late)

You must be proactive. The time to evaluate a supplier’s return policy is before you’ve placed your first order, not when you have a broken product and an angry customer waiting.

Step 1: Do Your Homework Before You Make Contact

The very first test is simple: can you easily find their return policy on their website? A confident supplier with a fair policy will make it prominent and easy to understand. If you have to dig through five layers of menus or read a 10-page legal document to find it, that’s a red flag. It suggests they are not proud of their policy.

Step 2: Ask the Tough Questions During the Vetting Call

Don’t just ask, “What’s your return policy?” Ask specific, scenario-based questions that reveal how their policy works in the real world.

“Can you walk me through your exact, step-by-step process if I receive a chandelier with a broken glass panel? What do I do, what do you do, and how long does it take to get a replacement?”

Their answer will tell you everything. This is just one of the critical questions you must ask any potential partner. Get our complete list of vetting questions in our comprehensive guide.

The Strategic Connection – Sourcing Models and Return Policies

A supplier’s return policy is not created in a vacuum. It is a direct result of their fundamental business model and logistical capabilities.

Why a Fair Return Policy is Nearly Impossible with Direct International Sourcing

If you source directly from an overseas factory, you are almost always on your own when it comes to returns. The simple, brutal math makes it impossible for them to offer a retailer-friendly policy. The cost of shipping a single defective item back across the ocean is often more than the item is worth. With no practical way to handle returns, the factory has little financial incentive to resolve the issue in your favor. This is one of the greatest hidden risks of direct importing. See the full picture in our guide to the hidden costs of sourcing overseas.

The Domestic Advantage: How a US Warehouse Enables a Great Return Policy

When a supplier has a warehouse on US soil, the entire dynamic changes. The process becomes simple, fast, and cost-effective. A return is just a domestic ground shipment away. This makes it easy for the supplier to stand behind their product, issue a credit quickly, and send a replacement from their existing US stock. The supplier’s location is often the single biggest predictor of their return policy quality. This is one of the most compelling reasons to choose a domestic partner, as we detail in our head-to-head comparison.

Conclusion: A Return Policy is a Litmus Test of a Supplier’s Character

A supplier’s return policy is not just a piece of boring fine print. It is a window into their soul. It reveals their confidence in their own products. It reveals their respect for your business as a partner. And it reveals their commitment to quality and customer service.

By learning to read and evaluate these policies, you can protect your profits, streamline your operations, and safeguard your hard-earned reputation. You are now equipped to look beyond the price list and the product photos to assess the true quality and integrity of any potential supplier. You can now choose a partner who will protect your business, not expose it to unnecessary risk.

Ready for a Partnership You Can Count On?

A great return policy is a cornerstone of a great partnership. It’s a promise of support. At Lighting Depot USA, we stand behind every product with a clear, fair, and hassle-free policy designed for the realities of retail.

Now that you know how to choose a secure partner, it’s time to integrate this decision into your complete strategy for success. Return to our ultimate guide for independent lighting retailers to build your comprehensive business plan.

About LightingDepotUSA

The LightingDepotUSA Editorial Team specializes in wholesale lighting trends, showroom strategies, and supply chain solutions tailored for independent retailers across the U.S. With years of experience in both manufacturing and distribution, we provide practical insights to help small businesses grow, reduce costs, and stay competitive.

View all posts by LightingDepotUSA