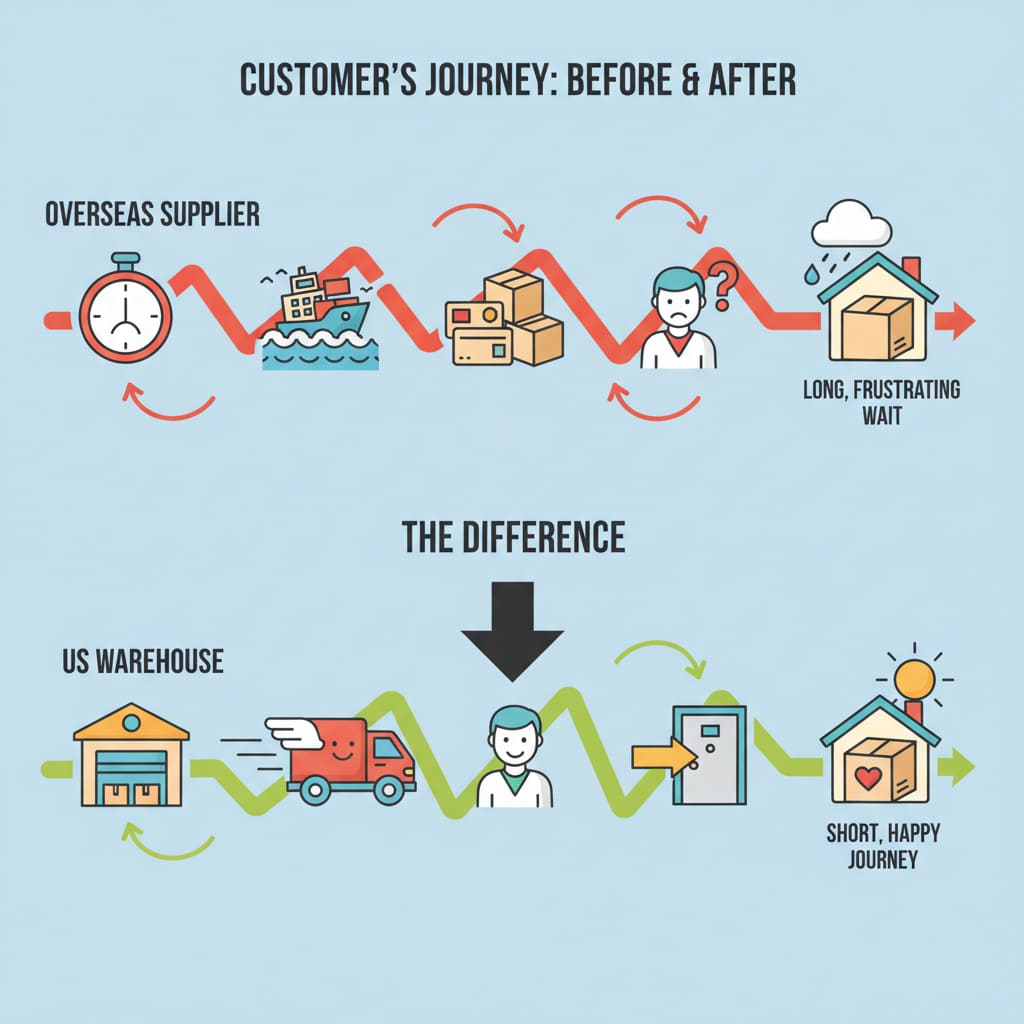

You just lost a $2,000 sale. The customer loved the chandelier. They were ready to buy. But they needed it in a week for their contractor. Your supplier’s lead time? Six to eight weeks from an overseas port. The customer walked out, pulled out their phone, and probably bought a similar-looking fixture on Amazon before they even reached their car.

This is the harsh reality of modern retail. Today’s customers, conditioned by the “get it tomorrow” world of e-commerce, have no patience for slow supply chains. For independent lighting retailers, this presents a massive challenge. Your expertise and curated selection can get a customer in the door, but if you can’t deliver the product quickly, you will lose the sale.

The good news? There is a powerful solution. By partnering with a supplier who strategically stocks inventory in a US-based warehouse, you can level the playing field and turn your supply chain from a liability into your greatest competitive advantage. This strategy is a critical component of building a resilient business, a topic we cover extensively in our ultimate guide for independent lighting retailers.

Table of Contents

What is a US-Based Warehouse Model?

Before we dive into the game-changing benefits, it’s crucial to understand what this model is—and what it isn’t. This isn’t about where a product is made; it’s about where it’s stocked. It’s a strategic choice that fundamentally changes how you do business.

Defining the Hybrid Model: Global Sourcing, Local Stocking

A supplier with a US-based warehouse operates on a smart hybrid model. They handle the immense complexity of global manufacturing and international importing themselves. They deal with the factories, the container ships, and the customs paperwork. Then, they strategically stock that inventory right here, on US soil, ready to ship to you. This gives you the cost benefits of a global supply chain without any of the logistical nightmares. You are no longer an importer; you are a retailer sourcing from a domestic distributor.

How Does This Differ from Standard Dropshipping?

It’s easy to confuse this with dropshipping, but they are worlds apart. While both models involve a third party shipping products, the US warehouse model gives you far more control and a much better outcome for your customer. With dropshipping, you often never see the product, which is shipped directly from an overseas factory with slow, unpredictable results. With a US-warehouse partner, the products are here, they’ve been quality-checked, and they ship quickly and reliably. The distinction is crucial for your brand’s reputation. We compare them in detail in our guide, Dropshipping vs. Local Warehousing: Which Model is Best for Your Lighting Store?

Why is Replenishment Speed the New Competitive Battleground?

In today’s market, speed is a key feature of your product. According to research by McKinsey, fast and reliable delivery is no longer a perk; it’s a core expectation for the majority of consumers. For independent retailers, you can’t always win on price, but you can absolutely win on service. When you combine your expert advice with the ability to get a product into a customer’s hands quickly, you create a powerful value proposition that online-only giants struggle to match. Fast replenishment isn’t just a logistical detail; it’s a strategic weapon.

The Core Advantage: Slashing Lead Times from Months to Days

The most immediate and dramatic benefit of a US-based warehouse is the radical reduction in the time it takes to get your products. This isn’t an incremental improvement; it’s a complete transformation of your business’s timeline.

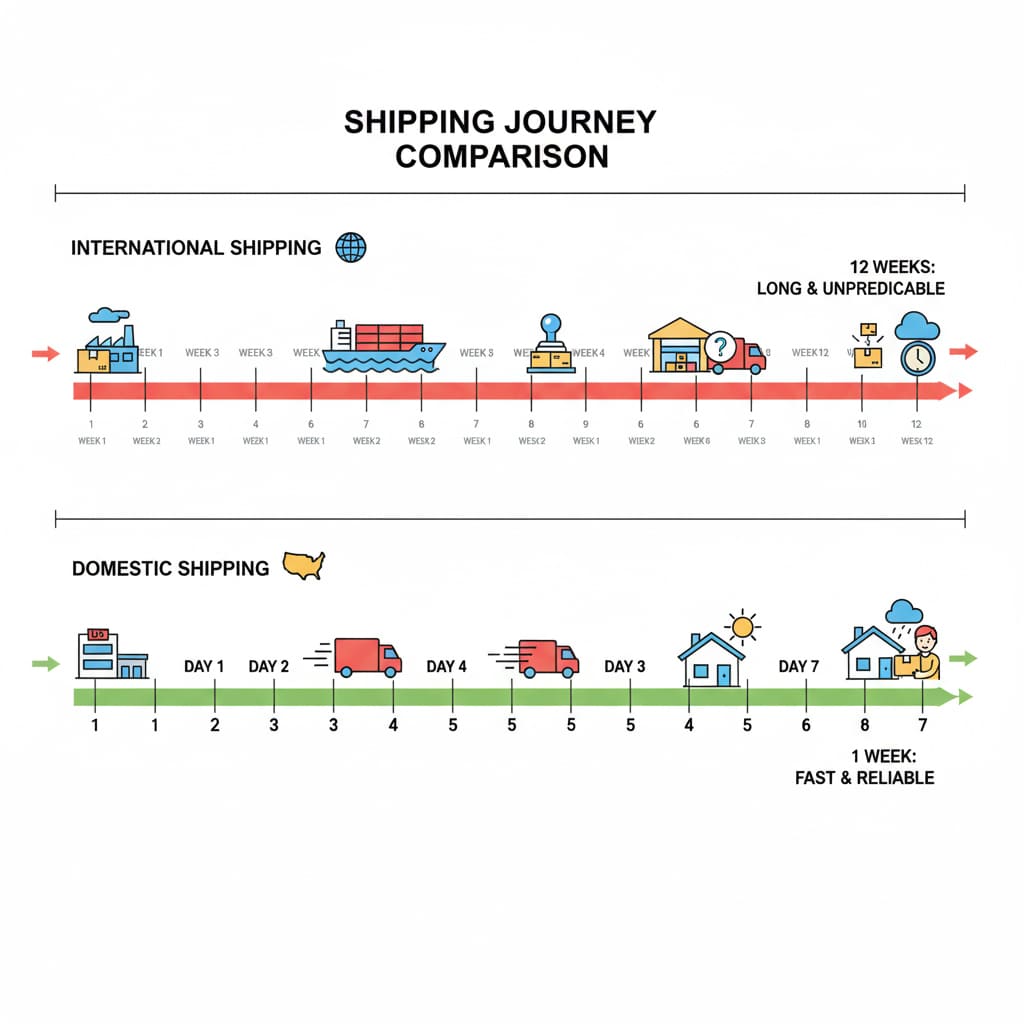

Anatomy of an International Order: A Painfully Slow Journey

If you’ve ever tried to source directly from overseas, this timeline will feel painfully familiar. It’s a long and uncertain path filled with potential delays at every step:

- Order Placement & Production: Your order waits in a queue before the factory even begins. (4-6 weeks)

- Inland Transit to Port: The finished goods are trucked from the factory to the shipping port. (1 week)

- Ocean Freight: The container ship slowly makes its way across the ocean. (4-5 weeks)

- Port Congestion & Unloading: Your container waits in line at a busy US port to be unloaded. (1-2 weeks)

- Customs Clearance: Your shipment navigates the complex world of import paperwork. (1 week)

- Inland Freight to You: The goods are trucked from the port to your showroom. (1 week)

The result? A staggering **total lead time of 12 to 16 weeks**. That’s an entire business quarter spent just waiting for your products to arrive.

Anatomy of a Domestic Warehouse Order: The Power of Proximity

Now, let’s look at the new reality. When you partner with a supplier stocking goods in the US, the journey is radically simplified:

- Order Placement: You place your order online. (Instant)

- Warehouse Picking & Packing: A professional team pulls your products and prepares them for shipment. (1-2 days)

- Ground Shipping to You: A domestic carrier like UPS or FedEx delivers the boxes to your door. (3-5 days)

The result? A lightning-fast **total lead time of 4 to 7 days**. You can order a lamp on a Monday and have it on your sales floor by Friday.

Comparison Table: The Shocking Difference in Lead Times

When you see the numbers side-by-side, the advantage becomes undeniable.

| Timeline Stage | Direct International Order | US Warehouse Order |

|---|---|---|

| Order Processing & Production | 4 – 6 Weeks | 1 – 2 Days |

| Transit Time | 6 – 8 Weeks | 3 – 5 Days |

| Total Lead Time | 10 – 14 Weeks | 4 – 7 Days |

| Time Reduction | Over 90% | |

What is the Real Business Cost of Long Lead Times?

The cost of waiting isn’t just measured in time; it’s measured in lost sales, damaged reputation, and missed opportunities. A stockout isn’t just one lost transaction; you may have lost that customer forever. Backorders create constant stress for your team and erode the trust you’ve worked so hard to build. Furthermore, a four-month lead time makes it impossible to react to the hot new trend that just exploded on social media. By the time your product arrives, the market may have already moved on.

The Overlooked Financial Wins of Domestic Stocking

Speed is a great story, but the financial impact is even better. Partnering with a domestic stocking supplier doesn’t just simplify your logistics; it strengthens your bottom line in ways you might not expect.

Eliminating the Retailer’s Burden of Import Costs

When you work with a US-warehouse partner, they become the “Importer of Record.” This is a crucial distinction. They are the ones responsible for paying all the complex and fluctuating costs associated with bringing goods into the country: import tariffs, customs brokerage fees, international freight, and port fees. These costs are simply bundled into the straightforward wholesale price you pay. You are no longer exposed to the risk of a sudden tariff increase or an unexpected shipping surcharge. This predictability is golden for financial planning. For a full picture of the dangers you’re avoiding, you need to understand the financial traps of direct importing. We uncover them all in Navigating the Hidden Costs and Risks of Direct Importing.

The Concept of “True Landed Cost”: A Price Tag Comparison

The price on a factory’s invoice is never the final price. The “True Landed Cost” is what you *actually* pay to get that product onto your shelf. Let’s compare:

| Cost Component | Scenario A: Direct Import | Scenario B: US Warehouse |

|---|---|---|

| Factory Price / Wholesale Price | $50.00 | $65.00 |

| Prorated International Freight | +$10.00 | Included |

| Import Tariffs (e.g., 10%) | +$5.00 | Included |

| Customs & Brokerage Fees | +$3.00 | Included |

| True Landed Cost | $68.00 | $65.00 |

In this realistic scenario, the “cheaper” import option is actually more expensive once all the hidden costs are accounted for. The US warehouse model provides price transparency and, often, a lower true cost.

Reducing Safety Stock: How Speed Lowers Your Inventory Investment

“Safety stock” is the extra inventory you are forced to buy simply to protect yourself against long and unpredictable lead times. It’s a hugely expensive insurance policy. When your replenishment is fast and reliable—just a few days away—you can dramatically reduce the amount of safety stock you need to carry. This single change can free up thousands, or even tens of thousands, of dollars in working capital. This is a key principle of a healthy retail business. Learn more in our essential guide on Cash Flow Management 101 for Independent Retailers.

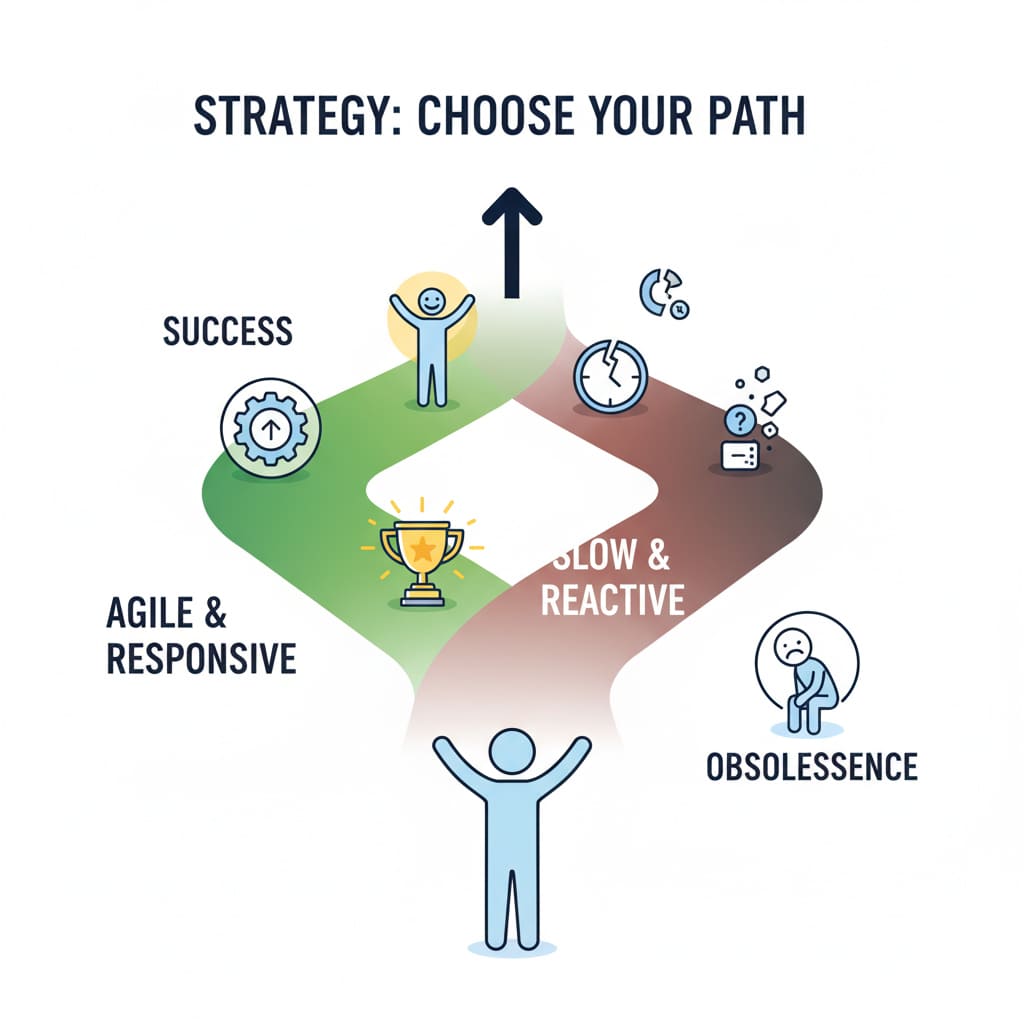

The Strategic Power of an Agile Supply Chain

This is where we move from tactics to true business strategy. A fast, reliable supply chain isn’t just about logistics; it’s about building a fundamentally more competitive and resilient business.

Your Secret Weapon Against Amazon: The Service + Speed Combination

How do you compete with an online behemoth? You lean into your strengths. Amazon’s weaknesses are its lack of true expertise and its impersonal service. Your strength is your ability to provide personalized, expert design advice. When you combine that high-touch service with a delivery speed that can rival or even beat their standard shipping, you create an unbeatable value proposition. Customers will choose the local expert who can solve their problem *and* get them the product quickly. This is how you win. Get more competitive strategies in our guide: 5 Ways for Small Lighting Stores to Compete with Amazon and Home Depot.

What is Business Agility? A Retailer’s Definition

“Agility is the ability to adapt and respond to change. In retail, it is the difference between leading the market and being left behind.”

A fast supply chain is the engine of business agility. Think about it. A local housing market suddenly booms? You can double your stock of popular builder-grade fixtures in a week. A new design trend explodes on TikTok? You can have it on your floor in ten days. A local competitor unexpectedly closes its doors? You can immediately launch a promotion to capture their customers, confident you can handle the extra demand. This ability to pivot quickly is priceless in today’s fast-moving market.

Enhancing Quality Control and Simplifying Returns

A US-based warehouse provides a critical checkpoint for quality. Your supplier can inspect goods upon their arrival from the factory, catching defects *before* they ever get to you. Furthermore, when a customer does need to return an item, the process is simple and fast. Contrast this with the logistical nightmare of trying to process a return with an overseas factory. This reliability not only saves you headaches but also builds customer confidence. A supplier’s return policy speaks volumes about their quality. Learn why in Why Your Supplier’s Return Policy Matters for Your Bottom Line.

How to Integrate a US-Warehouse Partner Into Your Business

You’re convinced. You see the power of this model. So, how do you make the switch? It’s about asking the right questions and taking a methodical approach to finding the perfect partner.

Key Questions for Your Potential Partner

When you’re interviewing a potential new supplier, go beyond their catalog. You need to investigate their logistics capabilities. Ask them directly:

- “Where is your US warehouse located, and can you provide average ground shipping times to my store’s zip code?”

- “What is your in-stock rate for your best-selling items?”

- “What is your standard order processing time from when I place an order to when it ships?”

- “What system do you use for order tracking and inventory updates?”

A confident, professional partner will have immediate and clear answers to these questions.

A Vetting Checklist: Beyond the Warehouse Location

A US warehouse is a critical piece of the puzzle, but it’s not the only piece. You still need to ensure the supplier is a good fit overall. Verify their product quality, check for safety certifications, and test their customer service responsiveness. A great warehouse is useless if the products are poor or the people are difficult to work with. Use our complete checklist to make a confident and informed decision.

Addressing Common Objections and Concerns

To be truly confident in this strategy, you need to understand the counterarguments. Let’s tackle the biggest and most common objection head-on.

Isn’t It Always Cheaper to Buy Directly from an Overseas Factory?

This is the great myth of direct importing. While the per-unit price tag on a factory invoice may look incredibly low, it is a dangerously incomplete number. As we’ve discussed, the “True Landed Cost” includes a host of other expenses that can quickly erode, and often erase, those initial savings. But the costs aren’t just financial. The unquantifiable costs of stress, uncertainty, and your own time spent managing complex logistics are immense. Every hour you spend tracking a container is an hour you aren’t spending with a customer on your showroom floor.

So, when does direct importing make sense? For massive national chains buying tens of thousands of units of a single, unchanging product, it is the correct model. For the vast majority of independent retailers, the risks, costs, and complexities far outweigh the potential savings. For a complete side-by-side analysis of the two models, be sure to read our guide: Domestic vs. International Lighting Suppliers: A Head-to-Head Comparison.

Your Supply Chain is Your Superpower

In the end, it comes down to this: you can’t have a 21st-century retail business with a 20th-century supply chain. A US-based warehouse isn’t just a logistical perk; it’s a fundamental strategic choice that enables you to be the kind of agile, responsive, and customer-focused business that can win in today’s demanding market.

It allows you to turn your inventory faster, protect your cash flow, delight your customers, and build a more resilient and profitable business. Stop letting a slow supply chain dictate your potential. It’s time to partner with a supplier built for the speed of modern retail.

Ready to Unleash Your Superpower?

Discover how Lighting Depot USA’s US-based warehouse can help you ship faster, stock smarter, and sell more. It’s time to build the supply chain your business deserves.

A fast supply chain is the engine of a thriving business. To see how it connects with your overall strategy for growth, return to our ultimate guide for independent lighting retailers.

About LightingDepotUSA

The LightingDepotUSA Editorial Team specializes in wholesale lighting trends, showroom strategies, and supply chain solutions tailored for independent retailers across the U.S. With years of experience in both manufacturing and distribution, we provide practical insights to help small businesses grow, reduce costs, and stay competitive.

View all posts by LightingDepotUSA