Domestic vs. International Lighting Suppliers: A Head-to-Head Comparison

The email lands in your inbox. It’s a price list from an overseas factory, and the numbers look almost too good to be true. It’s tempting. Very tempting. But is that price the full story, or just the first chapter of a long, expensive, and stressful saga?

As an independent lighting retailer, the decision of where to source your products is the most fundamental choice you will make. It will define your cash flow, your customer service, and your ability to compete. This isn’t just a choice between two shipping methods; it’s a choice between two completely different business models.

This guide will provide a brutally honest, data-driven comparison of both options. We will go beyond the surface-level price tag to uncover the true costs, risks, and strategic advantages of each, empowering you to make the right choice for your store. This sourcing decision is a crucial piece of your overall business strategy, a concept we explore in our ultimate guide for independent lighting retailers.

Table of Contents

Defining the Players: What Are We Really Comparing?

To have a clear discussion, we need to define our terms. These aren’t just vague concepts; they represent two distinct ways of doing business, each with its own set of responsibilities and risks that fall squarely on your shoulders.

What is an “International Supplier” in the Context of a Retailer?

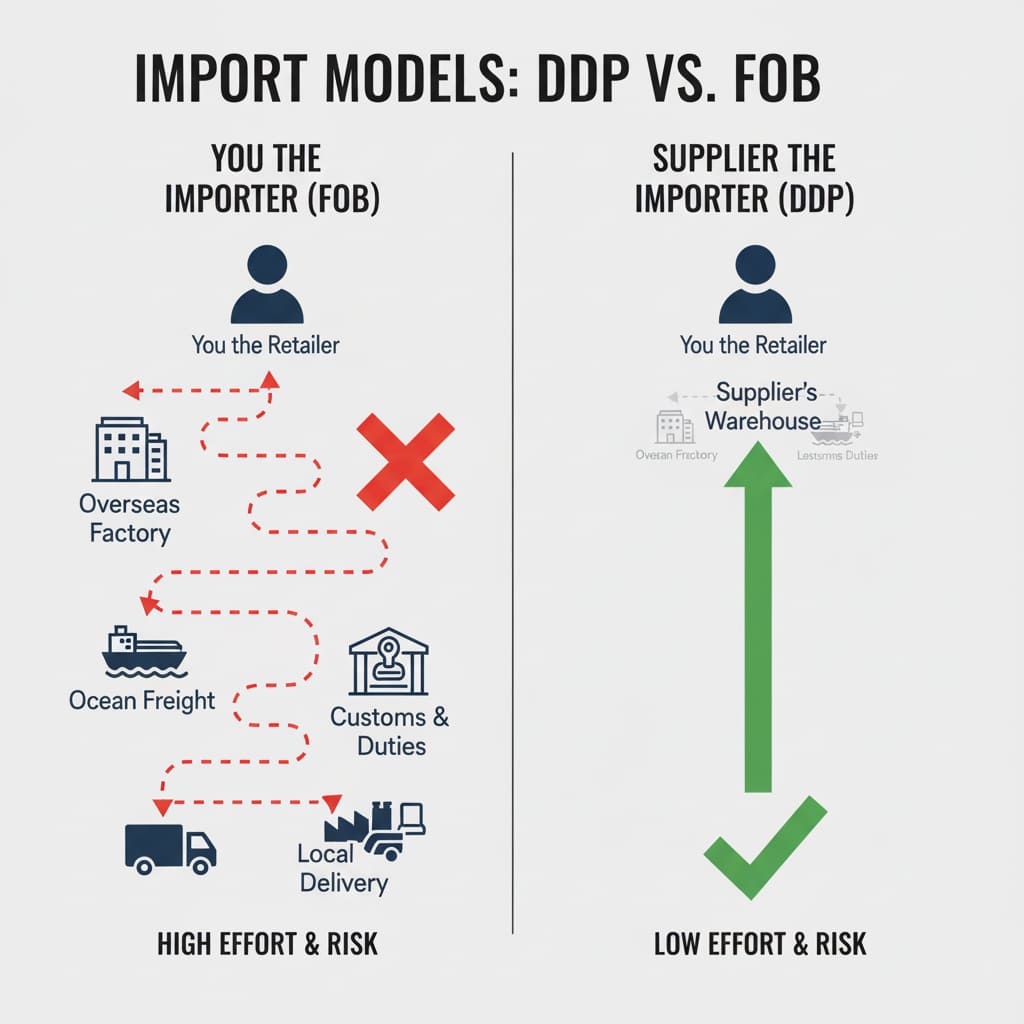

When we talk about sourcing internationally, we’re talking about the “Direct Sourcing” model. In this scenario, you, the retailer, become the importer. This means you are responsible for everything. You find the factory, you negotiate the terms, you handle the complexities of international wire transfers, and you are the one who has to arrange for freight forwarders, container ships, and US customs clearance. The factory’s job is essentially done once the container is loaded onto a ship. From that point on, all the risk, cost, and logistical headaches are yours.

What is a “Domestic Supplier” in the Modern Era?

A modern domestic supplier operates on a smarter “Hybrid” or “US-Warehoused” model. In this scenario, your supplier is the importer. They use their expertise and scale to manage the entire global manufacturing and importing process. They take on all the risks of international shipping and customs. The products are then strategically stocked right here on US soil, in their warehouse, ready to be shipped to you. For all practical purposes, you are buying from a domestic company. You are purchasing access to a streamlined, de-risked, and efficient supply chain.

The Head-to-Head Comparison: 6 Critical Factors

Now that we’ve defined the players, let’s put them in the ring. We’ll compare them across the six factors that matter most to an independent retailer’s success: speed, cost, risk, quality, communication, and flexibility.

Factor 1: Lead Time & Speed – The Battle of Months vs. Days

In today’s on-demand world, speed is not a luxury; it’s a core feature of your business. The difference in lead times between these two models is not just an inconvenience; it’s a fundamental strategic disadvantage.

The International Timeline: A 3-Month Marathon of Uncertainty

Sourcing directly from overseas is a long and perilous journey. A typical timeline looks something like this:

- Production & Waiting: 4 to 6 weeks for your order to be made.

- Ocean Freight: 4 to 5 weeks for a container ship to cross the ocean.

- Port & Customs: 2 to 3 weeks for your container to get through a congested port and clear US customs.

- Inland Trucking: 1 week to get from the port to your store.

The shocking reality? A total lead time of 12 to 16 weeks. You are placing a bet on what your customers will want an entire season from now.

The Domestic Timeline: A 1-Week Sprint to Your Doorstep

When your supplier’s warehouse is in the same country as your store, the process is radically simplified and accelerated:

- Order Processing: 1 to 2 days for the warehouse to pick and pack your order.

- Ground Shipping: 3 to 5 days for a domestic carrier to deliver to your door.

The result is a total lead time of 4 to 7 days. You can react to a sales trend on Monday and have the product on your floor by Friday. This speed is a game-changer, and its strategic impact is so profound we’ve dedicated an entire article to it. Discover why speed is your new superpower in The Importance of a US-Based Warehouse for Fast Replenishment.

Factor 2: Cost & Pricing – Uncovering the True Landed Cost

The low price on a factory’s price list is the tip of a very large and expensive iceberg. To make an honest comparison, you must calculate the “True Landed Cost”—the total cost to get a product from the factory floor to your showroom floor.

A Detailed Breakdown of Hidden International Costs

When you import directly, the factory price is just the beginning. You are also responsible for:

- International Freight & Insurance: The cost to ship a container across the ocean.

– US Customs Duties & Tariffs: Taxes imposed by the US government, which can be complex and change without warning.

– Customs Brokerage Fees: The fee you pay an expert to handle your import paperwork.

– Port & Drayage Fees: The cost to move the container off the ship and out of the port.

– Inland Transportation: The cost of trucking the container from the port to you.

These variable costs can add anywhere from 15% to 30% or more to your initial product cost. These are the financial traps that can turn a seemingly great deal into a disaster. Learn more in our guide, Navigating the Hidden Costs and Risks of Direct Importing.

Head-to-Head Cost Comparison Table

Let’s put real numbers to it. Here’s a realistic comparison for a single light fixture.

| Cost Component | International Direct Sourcing | Domestic Warehouse Sourcing |

|---|---|---|

| Factory / Wholesale Price | $50.00 | $65.00 |

| Prorated Freight, Tariffs, & Fees | +$18.00 | Included in Price |

| Your Time & Admin Cost | Significant (Managing the process) | Minimal (Placing a simple order) |

| True Landed Cost | $68.00+ | $65.00 |

As you can see, the domestic model provides cost predictability and is often the more affordable option when all factors are considered.

Factor 3: Inventory Risk & MOQ – The Cash Flow Battle

This is where the direct import model can be fatal for a small business. The Minimum Order Quantities (MOQs) required by overseas factories are often massive, forcing you to make huge, risky bets with your limited capital.

The High-MOQ Trap of International Sourcing

Factories are built for efficiency, which means they want to produce thousands of the same item at once. This results in MOQs that are often 500 or 1,000 units of a single SKU. For an independent retailer, this is a non-starter. It forces you to tie up tens of thousands of dollars in a single product that may or may not sell, suffocating your cash flow. If you’re struggling with this, the first step is to master the concept of MOQ. Read our essential guide: What is MOQ? A Small Retailer’s Guide to Minimum Order Quantities.

The Low-MOQ Freedom of Domestic Sourcing

A domestic supplier with a US warehouse has already taken the massive inventory risk for you. They buy in bulk so you don’t have to. This allows them to offer you incredibly flexible, low MOQs—often just a few hundred dollars for a mixed batch of products. This preserves your precious cash. See the direct impact this has on your finances in our guide to Cash Flow Management 101 for Independent Retailers.

| Factor | International Direct Sourcing | Domestic Warehouse Sourcing |

|---|---|---|

| Typical First Order | 500 units of one SKU @ $50/unit | Mixed batch of 20 SKUs |

| Upfront Cash Investment | $25,000 | $1,000 |

| Inventory Risk | Extremely High | Extremely Low |

Factor 4: Quality Control & Safety – The Risk of a Nightmare Scenario

What happens when the products you’ve waited three months for finally arrive, and they’re defective? This is the nightmare scenario for every direct importer.

The International Gamble: Discovering Defects a Continent Away

When you source directly, you are the final checkpoint for quality control. If you open a container and find that 30% of the fixtures are wired incorrectly or have cosmetic flaws, your recourse is extremely limited. The cost and complexity of shipping them back are prohibitive. You are often forced to either absorb the loss or try to sell substandard products, damaging your reputation.

The Domestic Safety Net: A US-Based Quality Checkpoint

A great domestic partner acts as your quality assurance agent. They inspect the products when they arrive at their US warehouse, identifying and dealing with any factory defects long before the products ever get to you. This domestic checkpoint is a crucial safety net. Furthermore, they are responsible for ensuring all products meet US safety standards. As an importer, that responsibility would fall on you. Don’t ever compromise on safety. Read our guide: Understanding UL and ETL Certifications.

Factor 5: Communication & Support – The Human Element

Business runs on clear communication. When your supplier is 12 time zones away and speaks a different language, even simple problems can become massive frustrations.

“The single biggest problem in communication is the illusion that it has taken place.” – George Bernard Shaw

A domestic partner means you have a team in your time zone, who speaks your language, and understands your market. When you have a question or an issue with a defective product, you can resolve it with a simple phone call, not a series of confusing late-night emails. This is especially critical when dealing with returns and warranties. A supplier’s return policy tells you everything you need to know about their commitment to partnership.

Factor 6: Flexibility & Agility – Your Strategic Superpower

The final factor is the most strategic. The sourcing model you choose directly determines your ability to adapt and respond to the market.

International Sourcing: The Slow-Turning Battleship

The direct import model, with its long lead times and high volume commitments, is like a giant battleship. It’s powerful, but it turns incredibly slowly. It locks you into buying decisions made months ago, making it impossible to react to a hot new trend or a sudden shift in the economy.

Domestic Sourcing: The Agile Speedboat

The domestic warehouse model is like a speedboat. It’s nimble and can change direction in an instant. It allows you to pivot your product mix, test new styles with minimal risk, and constantly keep your showroom fresh and exciting. This agility is your single greatest weapon in the fight against slower, larger competitors. Use this agility to your advantage and learn how to win against the giants.

The Verdict: Making the Right Sourcing Choice for YOUR Business

So, after comparing these two models head-to-head, which one is right for you? The answer depends entirely on the kind of business you are.

When Does Direct International Sourcing Actually Make Sense?

Let’s be clear and authoritative: this model is designed for a very specific type of business. It is the correct choice for massive, national chain stores. These companies have the deep pockets to absorb risk, the volume to justify huge orders, and entire departments dedicated to managing international logistics and legal compliance. For the 99% of independent retailers, this model is a recipe for cash flow problems, logistical nightmares, and unnecessary risk.

Why is the US-Warehoused Model the Definitive Choice for Independent Retailers?

The US-warehoused or “hybrid” model is tailor-made for the needs of the independent retailer. It minimizes risk, preserves cash flow, provides incredible speed and agility, and simplifies your operations so you can focus on what you do best: serving your customers. It is the smarter, safer, and more strategic choice.

A Final Decision-Making Checklist

Before you even consider direct importing, ask yourself these honest questions:

- Can my cash flow sustain a $25,000+ investment with no return for at least four months?

- Am I prepared to become an expert in international freight, customs law, and import tariffs?

- Is my business prepared to absorb the financial loss of an entire container of defective or damaged products?

- Is my business strategy built on selling massive volumes of a few items, or on offering a curated, agile selection?

Your answers to these questions will make the right path clear.

Your Sourcing Strategy is Your Business Strategy

The choice between a domestic and international supplier is far more than a logistical detail. It is a fundamental choice about the kind of business you want to build. One path is paved with high risk, slow reactions, and a constant battle for cash. The other path leads to agility, financial health, and the power to delight your customers.

You have the local expertise and the passion for design. By choosing the right supply chain model, you can build a business that is not only successful, but sustainable for years to come.

Ready to Build a Smarter Supply Chain?

It starts with choosing a partner who has built their business to support yours. Discover how Lighting Depot USA’s US-warehouse model gives you the power of a global supply chain with the simplicity of a domestic partnership.

Now that you’ve defined your sourcing strategy, integrate it into your complete plan for success. Return to our ultimate guide for independent lighting retailers to connect all the pieces.

About LightingDepotUSA

The LightingDepotUSA Editorial Team specializes in wholesale lighting trends, showroom strategies, and supply chain solutions tailored for independent retailers across the U.S. With years of experience in both manufacturing and distribution, we provide practical insights to help small businesses grow, reduce costs, and stay competitive.

View all posts by LightingDepotUSA