Table of Contents

What Exactly is a Low-MOQ Supplier?

Before we dive into the benefits, let’s get on the same page. Understanding these core concepts is the first step toward making smarter buying decisions.

A Simple Definition of Minimum Order Quantity (MOQ)

Think of MOQ as a “minimum buy-in.” It’s the smallest order a wholesale supplier is willing to fulfill. This can be measured in two main ways:

- Unit-Based MOQ: You must buy a minimum number of a single item (e.g., “at least 50 units of this pendant light”). This is common with direct factory orders.

- Value-Based MOQ: You must spend a minimum dollar amount across your entire order (e.g., “at least $500 worth of any products”). This model is far more flexible and retailer-friendly.

For a complete glossary of these terms and how they affect your business, it’s essential to start with the basics. Dive into our full guide: What is MOQ? A Small Retailer’s Guide to Minimum Order Quantities.

How is a “Low-MOQ” Supplier Different from a Traditional Wholesaler?

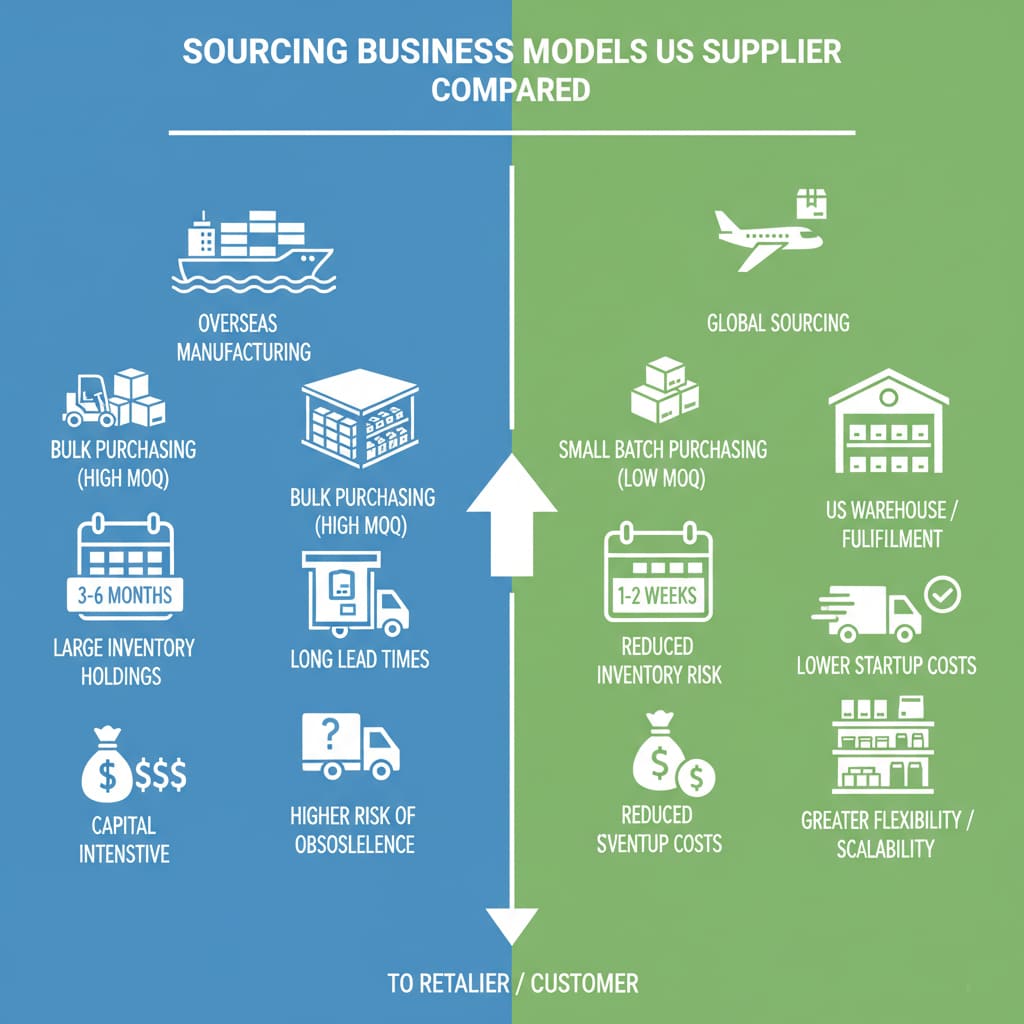

The difference is night and day. It’s about who the business model is built to serve. Traditional wholesalers are built for volume, catering to big-box chains. A modern, low-MOQ supplier is built for agility, catering to independent retailers like you.

| Characteristic | Traditional Wholesaler | Low-MOQ Supplier |

|---|---|---|

| MOQ Threshold | High (e.g., $10,000+ or hundreds of units) | Low (e.g., $500 – $1,000) |

| Capital Required | Very High | Very Low |

| Inventory Risk | High (You own it all) | Low (You only buy what you need) |

| Ideal Customer | National Chains | Independent Retailers |

Why Don’t All Suppliers Offer Low MOQs?

It comes down to economics and infrastructure. For a massive factory, stopping a production line to run a small batch is incredibly inefficient. Traditional importers who bring in containers full of one product have a business model based on volume. A true low-MOQ supplier, however, has invested in a different kind of infrastructure: a domestic warehouse and sophisticated inventory management. Their model is built on speed and flexibility, which allows them to serve smaller orders efficiently.

Benefit #1: Supercharge Your Cash Flow

Cash flow is the lifeblood of your business. It’s the oxygen that allows you to pay your rent, your staff, and yourself. When it’s trapped in unsold inventory, your business can’t breathe. This is the single most important benefit of a low-MOQ partnership.

The Problem: How High MOQs Trap Your Working Capital

Working capital is the money you have available to run your day-to-day operations. When a traditional supplier requires a $10,000 MOQ, you’re forced to convert that liquid cash into static boxes in your backroom. That’s $10,000 you can no longer use for a critical marketing campaign, a much-needed store renovation, or simply as a safety net for a slow month. It’s an incredibly risky position for any small business.

The Solution: The “Buy What You Need, When You Need It” Model

A low-MOQ model frees you from this trap. It allows you to place smaller, more frequent orders. Instead of one huge $10,000 order per quarter, you might place five $2,000 orders. This keeps your cash in your bank account for longer, giving you the power and flexibility to run your business proactively, not reactively. This is a core principle of sound financial planning. To learn more about managing your money effectively, explore our guide on Cash Flow Management 101 for Independent Retailers.

Practical Example: A Real-World Cash Flow Scenario

Don’t just take our word for it. Let’s look at the numbers. Here’s a simplified 3-month scenario comparing two identical stores with different buying strategies.

| Metric (3-Month Period) | Store A (High-MOQ Partner) | Store B (Low-MOQ Partner) |

|---|---|---|

| Initial Inventory Purchase | -$15,000 | -$3,000 |

| Monthly Sales | +$7,000 / month | +$7,000 / month |

| Monthly Replenishment Orders | $0 (Still selling through initial order) | -$1,500 / month |

| Operating Expenses | -$4,000 / month | -$4,000 / month |

| Cash Flow at End of Month 3 | -$6,000 (In the red!) | +$1,500 (Profitable & Flexible) |

As you can see, even with the exact same sales, Store B is in a vastly healthier financial position. They have positive cash flow and the flexibility to adapt, while Store A is in debt and still sitting on a mountain of inventory.

Benefit #2: Slash Your Inventory Risk

What’s the number one fear for any retailer? Buying a product you can’t sell. A low-MOQ partnership is the ultimate insurance policy against this risk, allowing you to be bold and experimental without betting the farm.

What is Dead Stock and Why is it so Dangerous?

“The greatest risk in retail is not in taking a chance on a new product, but in being stuck with the old ones.”

Dead stock is any product that hasn’t sold for an extended period (usually 6-12 months). It’s more than just a failure; it’s a financial anchor. It actively costs you money in storage and insurance, and its value depreciates every day it sits. Proactively identifying and liquidating this inventory is essential for a healthy business. If you’re struggling with this, you’re not alone. Get our complete strategy guide here: How to Reduce Dead Stock and Maximize Inventory Turnover.

The Freedom to Test: How to Pilot New Trends Without Fear

Here’s where a low-MOQ partner becomes your secret weapon. A trendy new style of pendant light is taking over Pinterest. With a traditional supplier, you’d have to commit to buying 100 of them. That’s a huge gamble. With a low-MOQ partner, you can add just five of them to your next mixed-batch order.

- If they sell out in a week? Great! You’ve found a winner. You can immediately reorder from the US-based supplier and have more in stock within days.

- If they don’t sell? No problem. The financial hit is tiny. You can mark them down and move on, armed with valuable market data.

This ability to test and adapt is a massive competitive advantage.

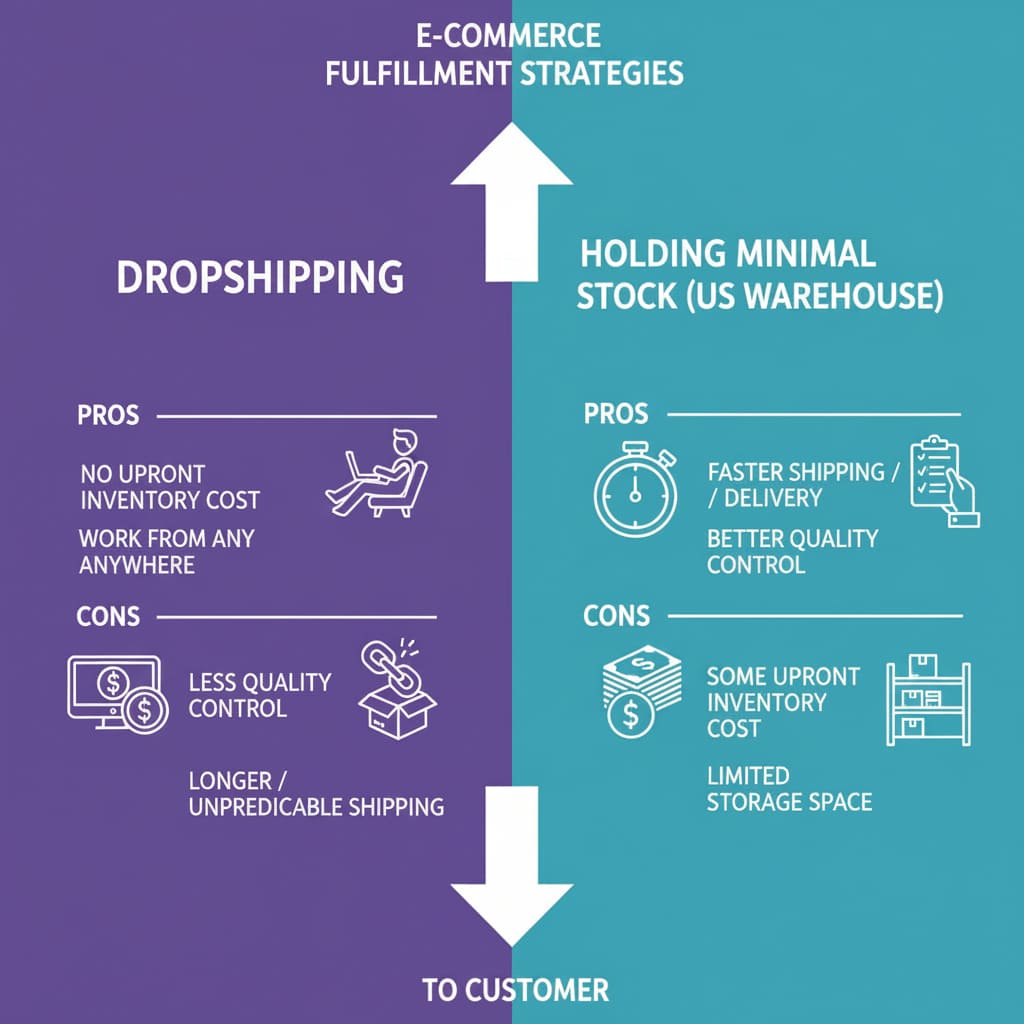

Comparing Risk: Dropshipping vs. a Low-MOQ Warehouse Model

Some retailers turn to dropshipping to eliminate inventory risk entirely. While it seems tempting, it comes with major trade-offs. You lose control over product quality, shipping times are often long and unpredictable, and profit margins are razor-thin. A low-MOQ partnership with a US-based warehouse offers the perfect compromise.

| Factor | Dropshipping | Low-MOQ Warehouse Model |

|---|---|---|

| Inventory Risk | Zero | Very Low |

| Quality Control | None (You never see the product) | Full (You can inspect items) |

| Shipping Speed | Slow & Unpredictable (Often from overseas) | Fast & Reliable (From a US warehouse) |

| Profit Margin | Very Low | High |

| Customer Experience | Poor | Excellent |

The low-MOQ model gives you the best of both worlds: minimal financial risk combined with maximum control over your brand and customer experience. To make the best choice for your store, it’s wise to weigh all the options. We compare these two popular models head-to-head in our detailed guide.

Benefit #3: Offer a Wider, More Dynamic Product Catalog

You can’t compete with the big-box stores on sheer volume. But you can easily beat them on curation, style, and newness. A low-MOQ partner is the key that unlocks your ability to offer a surprisingly large and ever-changing selection.

The “Endless Aisle” Concept for Physical Retailers

Your showroom’s physical space is limited, but your potential catalog isn’t. Your supplier’s entire catalog becomes your “endless aisle.” You can showcase your bestsellers on the floor and use a tablet or a screen to show customers hundreds of other options available to order. Because your partner has the items stocked in a US warehouse, you can confidently promise fast delivery, turning your small showroom into a portal to a massive virtual inventory.

Staying Ahead of Trends: How to Keep Your Showroom Fresh

Nothing is less inspiring than a store that looks the same year after year. A low-MOQ model allows you to constantly inject newness into your showroom. You can dedicate a small portion of your budget each month to bringing in a handful of new, exciting pieces. This gives your loyal customers and local designers a reason to keep coming back. They know there will always be something new to discover at your store. Not sure what to test next? Start by exploring popular styles like Modern Farmhouse or dive into the timeless appeal of Mid-Century Modern.

Case Study: How “The Lightbox” Doubled its Selection Without Increasing Costs

Consider the case of a fictional but typical store, “The Lightbox.” Previously, they spent their entire $20,000 inventory budget on 100 SKUs from a high-MOQ supplier. After switching to a low-MOQ partner, they reinvested just $10,000 to stock their showroom with 200 different SKUs in smaller quantities. The result? Their inventory cost was cut in half, their cash flow soared, and customers raved about their amazing new selection. This is the power of strategic sourcing.

Benefit #4: Increase Your Profitability and Margins

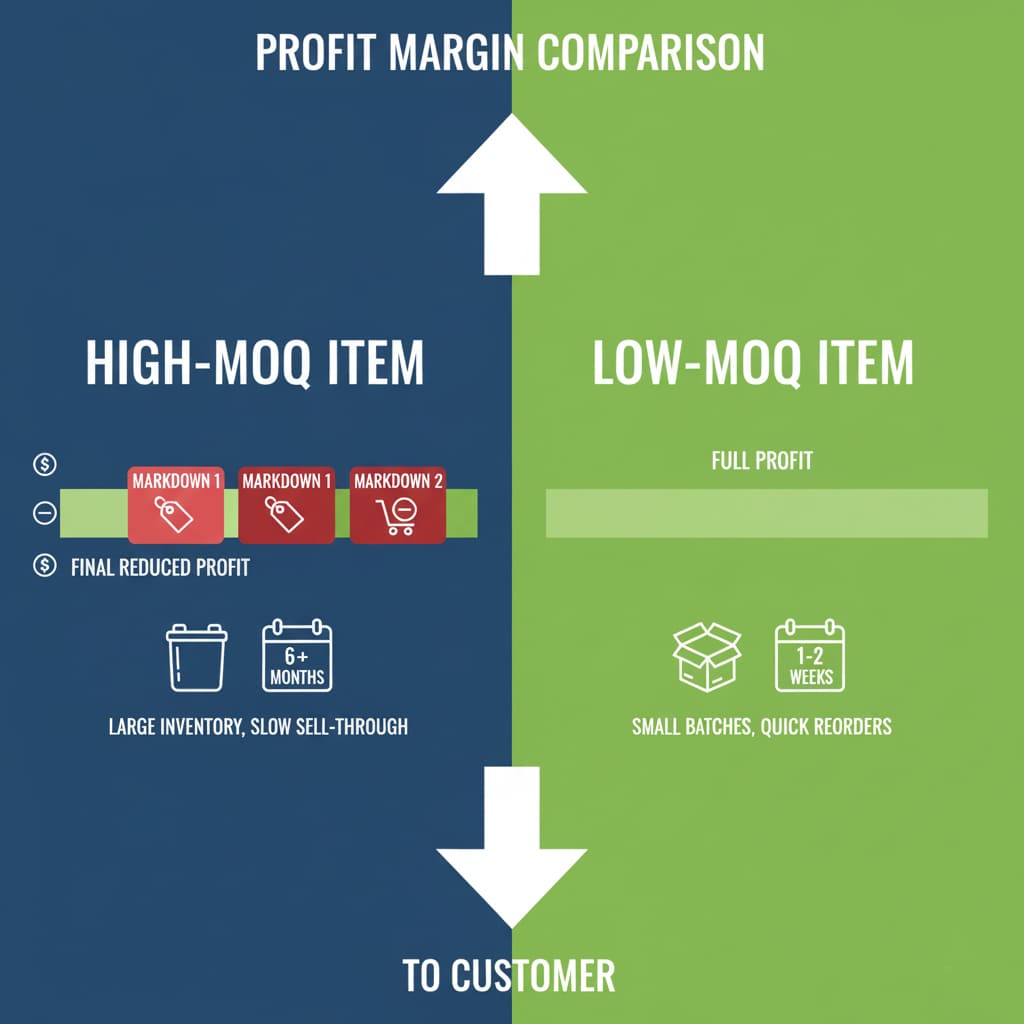

It seems counterintuitive. How can buying in smaller quantities actually make you more money? It’s because true profitability isn’t about the price you buy for; it’s about the price you *sell* for.

The Myth of the “Lowest Unit Price”

That rock-bottom unit price on an order of 1,000 chandeliers from overseas is a siren’s song. It looks great on paper, but it ignores a mountain of hidden costs. The true cost of that fixture includes international shipping, import tariffs, customs fees, and the risk that a third of them will have to be sold at a deep discount because the trend has passed. The slightly higher unit price from a domestic, low-MOQ supplier is often the *truly* cheaper option once all factors are considered.

| Cost Factor | High-MOQ Import Model | Low-MOQ Domestic Model |

|---|---|---|

| Unit Cost | $50 | $60 |

| Prorated Shipping & Tariffs | +$15 | +$5 (Included in wholesale price) |

| Storage & Risk Cost (10%) | +$5 | $0 |

| True Landed Cost per Unit | $70 | $65 |

Reducing Markdowns: The #1 Way to Protect Your Margins

The fastest way to destroy your profit margin is a clearance sale. When you’re forced to mark down a $200 lamp to $100 just to get it out the door, you’ve likely lost money. Because a low-MOQ model allows you to buy in smaller, more strategic quantities, the need for these profit-killing sales plummets. You sell more of your inventory at full price, which is the key to a healthy bottom line.

A Smarter Pricing Strategy Fueled by Flexibility

When you aren’t terrified of being stuck with inventory, you can price your products with more confidence. You can hold firm on your margins for unique, high-demand items and strategically discount to drive traffic, all without the desperation that comes from having a warehouse full of aging stock. This flexibility is a cornerstone of a modern pricing approach. Learn how to price your products for maximum profitability in our comprehensive guide.

Benefit #5: Build a Stronger, More Agile Business

The final benefit is the most profound. A low-MOQ supply chain doesn’t just change your finances; it changes the entire DNA of your business, making it more resilient, adaptable, and future-proof.

Increased Business Agility: Adapting to Market Shifts in Weeks, Not Months

Imagine a new design trend explodes on social media. With a traditional supply chain, it would take you 6-9 months to get that product on your floor. By then, the trend might be over. With a low-MOQ partner stocking products in the US, you can react in weeks. This agility allows you to ride trends as they’re cresting, not after they’ve crashed. It’s the difference between leading the market and following it.

Building a True Partnership with Your Supplier

The high-volume model creates a purely transactional relationship. The low-MOQ model fosters a genuine partnership. Your supplier’s success is directly linked to yours. They need you to sell through your inventory so you can reorder. This creates a collaborative dynamic where they are motivated to provide you with marketing support, product data, and trend insights. It’s a relationship built on mutual growth. Of course, finding this kind of partner requires careful evaluation. Learn what to look for in our essential guide on how to vet a wholesale supplier.

Competing Effectively Against the Giants

This is how you win. You can’t be bigger, but you can be faster. You can’t be cheaper on every item, but you can be smarter with your capital. A low-MOQ, domestic-stocking model is the great equalizer. It is the secret weapon that allows the independent retailer to leverage their local expertise and curated taste with the supply chain efficiency once reserved for the giants. It’s the key to not just surviving, but thriving. This is how you turn your size into your greatest strength and effectively compete in today’s market.

Your Next Step to Smarter Sourcing

The message is clear: the old way of buying inventory is holding your business back. A low-MOQ partnership is your key to unlocking cash flow, slashing your risk, offering a more exciting catalog, boosting your profits, and building a business that’s ready for the future.

This isn’t just a trend; it’s a fundamental shift in how successful independent retailers operate. Are you ready to make the change?

Ready to Experience These Benefits?

Stop letting your inventory control your business. Take control of your inventory. Discover how our low-MOQ, US-based warehouse model can transform your store and your bottom line.

This inventory strategy is a powerful tool. To see how it fits into your complete business plan, return to our ultimate guide for independent lighting retailers

About LightingDepotUSA

The LightingDepotUSA Editorial Team specializes in wholesale lighting trends, showroom strategies, and supply chain solutions tailored for independent retailers across the U.S. With years of experience in both manufacturing and distribution, we provide practical insights to help small businesses grow, reduce costs, and stay competitive.

View all posts by LightingDepotUSA