How to Vet a Wholesale Lighting Supplier: 7 Critical Questions to Ask

Choosing a wholesale supplier is like choosing a co-pilot for your business. A great one helps you navigate turbulence, spots opportunities you might have missed, and makes the entire journey smoother and more profitable. A bad one? They can lead you straight into a storm.

The market is flooded with suppliers all promising the best products and the lowest prices. It’s noisy. It’s confusing. So how do you cut through the marketing fluff and find a true partner who is genuinely invested in your success? You need a system. A professional, repeatable vetting process. This guide is that system. We’ve built it around 7 critical questions that will strip away the sales pitch and reveal the true character and capability of any potential supplier.

This is one of the most important decisions you’ll make. Let’s make sure you get it right. Choosing the right partner is the final, crucial step in building a successful retail business, a topic we introduce in our ultimate guide for independent lighting retailers.

Table of Contents

Question 1: Beyond the Pretty Pictures – How Do You Guarantee Quality and Safety?

This question must always come first. Why? Because nothing else matters if the product is poorly made or, even worse, unsafe. The quality of the products you sell is a direct reflection of your own brand’s integrity.

Why This is the Most Important Question You Will Ask

A faulty fixture isn’t just an inconvenience; it’s a breach of trust with your customer. It leads to frustrating returns, negative reviews, and a damaged reputation that can take years to rebuild. More seriously, selling an uncertified or poorly constructed electrical product opens your business up to immense legal and financial liability. This isn’t just about finding pretty lights; it’s about protecting your business and your customers.

Drilling Down: Specific Sub-Questions to Uncover the Truth

A vague question gets a vague answer. You need to ask specific, probing questions to understand their commitment to quality:

- “Can you walk me through your quality control (QC) process, both at the factory level and at your US warehouse?”

- “Are all of your products UL or ETL certified for sale in the United States? Can you provide proof of this certification?”

- “What specific materials are used in your bestselling fixtures? For example, is this chandelier solid brass or plated steel?”

- “Can you provide detailed specification sheets, including wiring diagrams and installation manuals, for your products?”

What to Look For: The Hallmarks of a Quality-Obsessed Supplier

Pay close attention to how they answer. A great partner will be excited to answer these questions.

| Green Flags ✅ (Signs of a Great Partner) | Red Flags 🚩 (Signs of a Risky Partner) |

|---|---|

| Eagerly provides detailed spec sheets and safety documentation. | Hesitates or is unable to provide safety certifications. |

| Openly and confidently discusses their multi-stage QC process. | Gives vague answers like, “we work with very good factories.” |

| Proudly highlights the quality of their materials and components. | Prices seem “too good to be true” (often a sign of cheap, untested components). |

The Non-Negotiable: Understanding Safety Certifications

The UL and ETL marks are not suggestions; they are your assurance that a product has been independently tested by a Nationally Recognized Testing Laboratory (NRTL) and meets stringent US safety standards. Think of it as a seal of approval from a trusted third party. Selling products without these marks is a massive risk you should never take. Highlighting these certifications to your customers is also a powerful way to differentiate your quality from anonymous online sellers. This topic is so critical that it deserves its own deep dive. Learn more in our essential guide: Understanding UL and ETL Certifications: A Must-Know for US Lighting Retailers.

Question 2: The Make-or-Break Question – What is Your Real-World Logistics Plan?

A supplier can have the best products in the world, but if they can’t get them to you reliably and efficiently, they are a liability. A supplier’s logistics model will directly determine your business’s agility, customer satisfaction, and ultimately, its profitability.

The Critical Sub-Questions About Their Operations

You need to understand their entire operational process, from the moment you click “buy” to the moment the boxes arrive at your door.

- “Where is your primary warehouse located for shipping to US retailers?”

- “What is your average order processing time—the time it takes from order placement to the order shipping out?”

- “Based on my store’s zip code, what are your typical ground shipping transit times?”

- “What is your average in-stock rate for your top-selling products? How do you communicate backorders?”

A Tale of Two Models: International vs. Domestic Warehouse

The location of your supplier’s inventory is a game-changing detail. A supplier shipping directly from overseas operates on a timeline of months. A supplier stocking products in a US warehouse operates on a timeline of days. This single difference impacts every aspect of your business, from cash flow to customer happiness. The advantages of a domestic warehouse are so profound that we’ve dedicated an entire article to it. Discover why this is a non-negotiable for modern retailers in The Importance of a US-Based Warehouse for Fast Replenishment. For a complete financial breakdown of the two approaches, you can also read our guide: Domestic vs. International Lighting Suppliers: A Head-to-Head Comparison.

Question 3: The Money Talk – What Are Your Complete Purchasing Terms?

Now we get to the numbers. A healthy partnership requires financial terms that work for both parties. It’s crucial to understand the complete financial picture before you commit, looking beyond just the per-unit price tag.

Essential Financial and Policy Questions to Ask

A professional supplier will have clear, straightforward answers to these questions.

- “Could you please provide your full wholesale price list, including any tiered pricing for larger orders?”

- “What are your standard payment terms for a new retail partner? Do you offer Net 30 accounts?”

- “What is your Minimum Order Quantity (MOQ) policy? Is it based on units or dollar value? Is there flexibility for a smaller trial order?”

- “Are there any additional fees I should be aware of, such as order handling fees, small order fees, or freight surcharges?”

A Comparison of Common Pricing and MOQ Models

The supplier’s MOQ policy is a direct signal of who their business is built to serve. Understanding the different models helps you find a partner whose policies align with your independent retail strategy.

| Model Type | Description | Who It’s For | Risk Level |

|---|---|---|---|

| High MOQ / Low Unit Price | Requires large, single-product orders but offers the lowest per-unit cost. | Big-box chains, national retailers. | High |

| Low MOQ / Tiered Pricing | Low entry point with discounts that reward larger, mixed-batch orders. | Independent retailers, growing businesses. | Low |

| Dropshipping | No inventory held by the retailer; supplier ships single items directly to the end customer. | Online-only businesses, market testers. | Zero Financial, High Brand Risk |

For most independent showrooms, a low-MOQ model with tiered pricing offers the perfect blend of flexibility and growth potential. It is arguably the most critical financial term for a small business. You can master this concept with our complete guide: What is MOQ? A Small Retailer’s Guide to Minimum Order Quantities. This purchasing strategy is the foundation of your own retail pricing. Learn how to translate wholesale costs into profitable retail prices in our pricing strategy guide.

Question 4: When Things Go Wrong – What is Your Support and Return Policy?

Any supplier can look good when a sale goes perfectly. But the true test of a partner’s character and integrity is how they behave when something goes wrong. A clear, fair, and hassle-free process for handling issues is a sign of a confident, professional organization.

“The quality of a partnership is not measured in the easy times, but in how challenges are resolved together.”

The “Must-Know” Questions About Their Return Process

Don’t wait until you have a broken fixture and an angry customer to figure out their policy. Ask upfront:

- “What is your exact process if a product arrives damaged in shipping?”

- “What is the warranty period on your products, and what does it specifically cover?”

- “If a product is defective, who is responsible for the cost of return shipping?”

- “Do you issue a credit to my account or send a replacement unit for approved returns?”

Decoding the Policy: What to Look For and What to Avoid

A supplier’s return policy is a direct reflection of their confidence in their products. A convoluted policy is often a deliberate tactic to minimize their own liability. Be wary of “all sales final” clauses or high restocking fees, especially for defective merchandise. A great partner stands behind their product and makes it easy to make things right when a problem occurs. This is more than just a policy; it’s a critical component of your own profitability. We explain the financial impact in our guide: Why Your Supplier’s Return Policy Matters for Your Bottom Line.

Question 5: The Human Connection – Who Will I Be Working With?

In a world of automation, the ability to connect with a knowledgeable human being is a competitive advantage. You need to know who you’ll be talking to when you have a question, a problem, or a special request.

Specific Questions About Their Support Structure

- “Will I have a single dedicated sales representative or account manager who knows my business?”

- “What are your customer service hours, and what is your typical email or phone call response time?”

- “Do you have a team that can provide technical support for product questions or complex installation issues?”

- “How do you proactively communicate important information, like shipping delays or backorders?”

Comparing Support Models: Dedicated Rep vs. General Queue

There is a massive difference between having a dedicated rep who understands your store’s unique needs and being thrown into a generic customer service queue every time you call. A dedicated rep becomes an extension of your team. They can alert you to new products that fit your style, help you resolve issues quickly, and advocate for you within their organization. It’s a key indicator of a supplier’s commitment to building a true partnership.

Question 6: The Alignment Question – Are We a Good Fit for Each Other?

This is a strategic question designed to uncover a supplier’s core business philosophy. You want to partner with a company whose goals are aligned with yours, not one that sees you as just another small account.

Why You Need a Partner, Not Just a Vendor

A vendor simply sells you products. A partner is invested in helping you *sell through* those products. A vendor’s job is done when the invoice is paid. A partner’s job is done when your business grows. This question helps you determine which one you’re talking to.

Uncovering Their True Focus with These Questions

- “Could you describe your ideal retail partner? What types of businesses do you work with most successfully?”

- “Do you sell your products directly to consumers on your own website? If so, how do you prevent channel conflict with your retail partners?”

- “What kind of marketing support do you provide? Do you have high-resolution images, detailed product data, or lifestyle photos that I can use?”

- “How do you gather feedback from retailers like me to help shape your future product development?”

The answers here are incredibly revealing. If their “ideal partner” sounds nothing like you, or if they are actively competing with you online, it’s a clear sign of misalignment. A great partner sees you as a vital sales channel and provides you with the tools you need to succeed. These tools are often the key to outsmarting your larger competitors. Find more strategies in our guide: 5 Ways for Small Lighting Stores to Compete with Amazon and Home Depot.

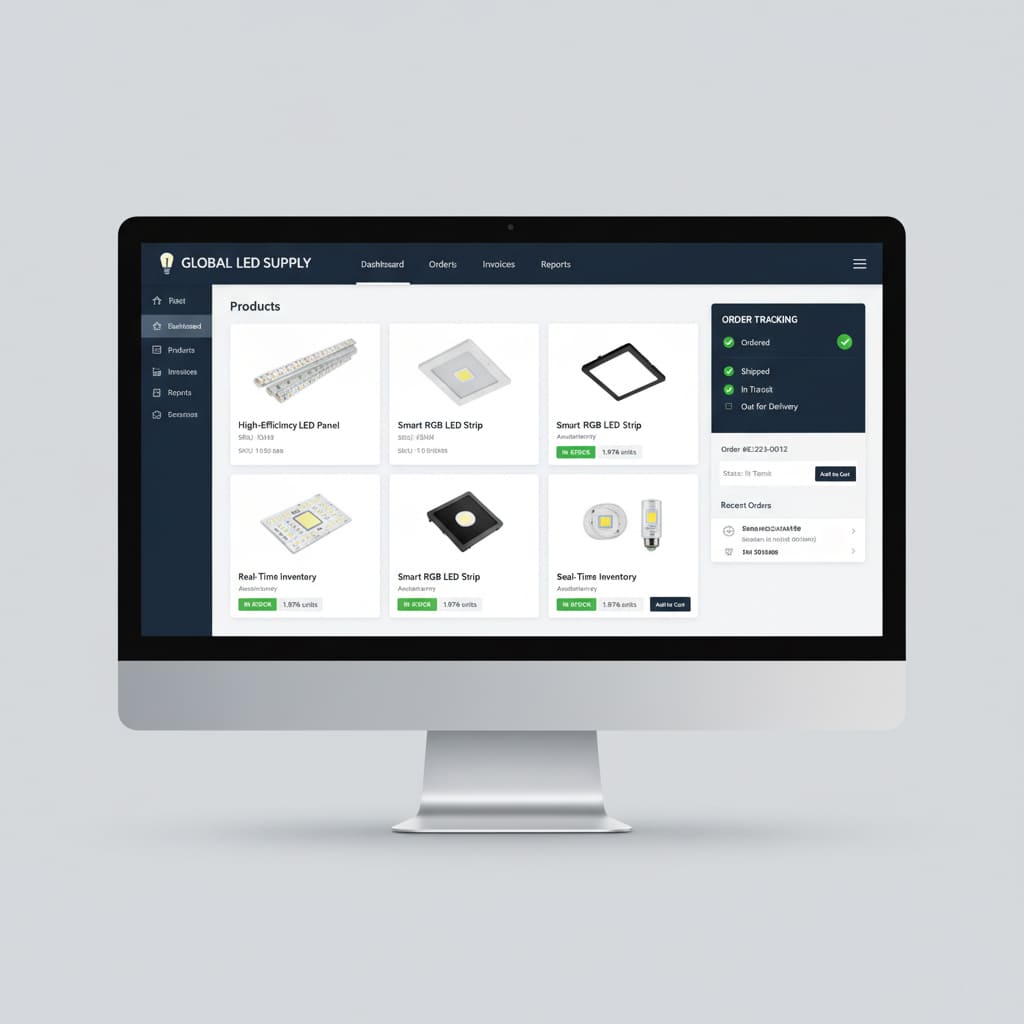

Question 7: The Efficiency Question – How Will Your Technology Help Me Operate?

A supplier’s technology platform—or lack thereof—is a window into their modernity and efficiency. The right tech saves you time, reduces costly errors, and empowers you with data. An outdated system will burden you with hours of manual, frustrating work.

The Modern Retailer’s Tech Checklist for Suppliers

In today’s market, these are not luxuries; they are necessities.

| Technology Feature | Why It’s Critical for You |

|---|---|

| Online B2B Ordering Portal | Allows you to place orders 24/7 without waiting for a sales rep. Reduces errors. |

| Real-Time Inventory Levels | Lets you see what’s actually in stock before you promise it to a customer. Prevents backorders. |

| Automated Order Tracking | Saves you from having to call or email for a simple status update. |

| Product Data Feeds (e.g., CSV, API) | Allows for easy import of product information into your own website or Point-of-Sale system. |

A supplier who has invested in this technology is demonstrating a commitment to making your life easier and your business more efficient.

Bonus: Your Vetting Process in Action – A Step-by-Step Checklist

Knowledge is power, but a process is what turns that power into results. Here is a simple, step-by-step checklist you can use to vet any potential supplier professionally and thoroughly.

✅Step 1: Online Reconnaissance. Before you even make contact, do your homework. Does their website look professional? Do they have a social media presence? What are other businesses saying about them?

✅Step 2: The Interview. Schedule a call. Use the 7 critical questions in this guide as your agenda. Take detailed notes on not just what they say, but how they say it.

✅Step 3: The Test Drive. Place a small, low-risk sample order. This is the ultimate test. Evaluate everything: the ordering process, the shipping speed, the quality of the packaging, and, of course, the product itself.

✅Step 4: The Reference Check. Ask for references from a few other independent retailers in a non-competing market. A confident supplier will be happy to provide them.

✅Step 5: The Final Decision. Review all your findings. Trust your data and your gut. Make a confident, evidence-based decision to commit to a partnership.

Choose a Partner, Not Just a Price List

The vetting process is not a chore; it is a crucial investment in the future of your business. It’s the difference between building your dream on a foundation of solid rock versus shifting sand. By asking these tough, specific questions, you move beyond the sales pitch and find a true partner who is equipped and motivated to help you succeed.

Ready to Find a Partner Who Checks Every Box?

At Lighting Depot USA, we built our business on transparency and a dedication to the success of independent retailers. We invite you to put us to the test. Let’s start the conversation.

Once you’ve chosen the right partner, you’re ready to build a thriving business. Integrate this decision into your overall strategy by returning to our ultimate guide for independent lighting retailers.

About LightingDepotUSA

The LightingDepotUSA Editorial Team specializes in wholesale lighting trends, showroom strategies, and supply chain solutions tailored for independent retailers across the U.S. With years of experience in both manufacturing and distribution, we provide practical insights to help small businesses grow, reduce costs, and stay competitive.

View all posts by LightingDepotUSA